Optimising manufacturing production and quality assurance

When it comes to manufacturing, one mistake can bring the whole process to a standstill.

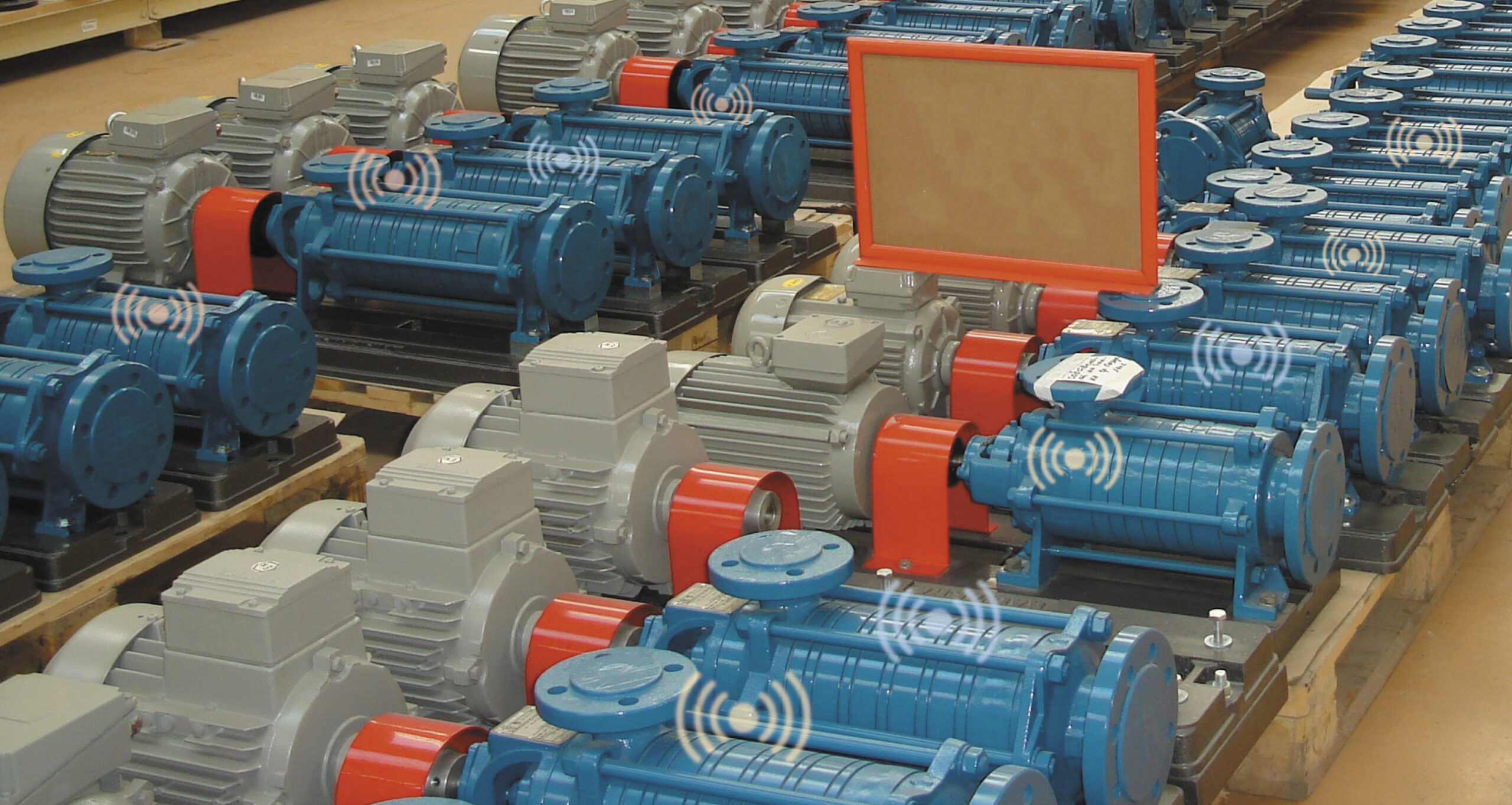

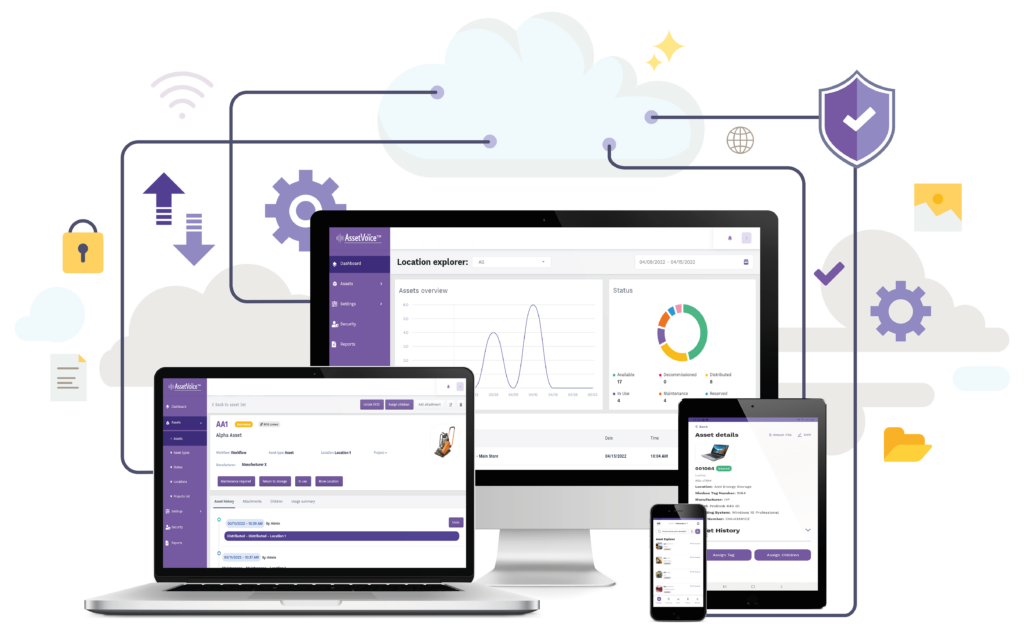

AssetVoice™ promotes automation to eliminate bottlenecks and save costs in your manufacturing process. Our award-winning asset tracking and management of change software uses RFID technology, smart sensors, and cloud services to monitor, track, and manage critical equipment and spare parts.

AssetVoice™ aims to digitise the process flows and empower teams with real-time tracking, intelligence, and analytics about anything you need to know in the manufacturing line, including but not limited to:

- Location and progress of items/assets on the manufacturing belt

- Unexpected asset movements and condition changes

- Palettes that are sent out from the factory or facility

- Current states and locations of equipment, spare parts and any faulty machinery

- Inventory levels and alerts for procurement requirements and stock replenishment

- Accurate asset and associated information and specifications

- Repair, inspection and location data and history

- Adherence to procedures and processes using checklists

- Other bespoke needs and requirements

How AssetVoice™ will enhance your manufacturing process

Maximise production

Identify bottlenecks in your production line by quickly recognising any equipment failures and reducing time wasted by people looking for spares to bring assets back online

Save money

Using real-time data and automation, you can remove the risk of overstocking spare parts, complete repairs faster and ensure an efficient workflow to reduce the cost of equipment downtime

Boost productivity

Eliminate lost time and improve staff productivity by sending notifications to your team instead of having them wait for managers to instruct them to do something

Adhere to processes and procedures

Ensure compliance with your organisation’s manufacturing system using AssetVoice workflows, where you can log any skipped steps or use built-in checklists and photo attachments to identify any reported failures

Make data-informed decisions

Gain access to customised reports – such as asset failure tracking – to accurately interpret performance, identify improvements and recognise how quickly you are responding to problems to minimise lost production time and impact on plant safety

Enhance visibility and turnaround time

Know exactly what you have and where inventory is located at the click of a button to eliminate wasted time searching for inventory

Watch AssetVoice™ in action

Get in touch! By registering your interest in AssetVoice™, you can:

- Book a demo of the software

- Get more details about the software and hardware solutions

- Receive ongoing insights and advice for asset tracking and labelling initiatives